An incinerator is a furnace meant for burning harmful gadgets in a combustion chamber, the place incineration is carried out.

Burning probably harmful supplies at temperatures excessive sufficient to eradicate pollution is called incineration. Incineration is mostly used the place there’s a large-scale accumulation of waste and when treating cumbersome heterogeneous waste wants therapy. It could deal with varied hazardous pollution, together with soil, sludge, liquids, and gases. In distinction to the inorganic content material of trash, which helps to generate ash, the natural portion of rubbish will get burned and produces warmth. Ash, warmth, and combustion gases are the ultimate byproducts of incineration. Though incineration eliminates varied harmful substances, together with solvents, PCBs (polychlorinated biphenyls), and pesticides, it doesn’t eradicate metals like lead and chromium.

Stable, liquid, and gaseous waste from manufacturing processes is safely disposed of utilizing incinerators. By the usage of auxiliary equipment like steam boilers, they can be utilized to generate electrical energy by warmth or steam move. To minimize their detrimental results on the atmosphere, fashionable incinerators use air air pollution management know-how.

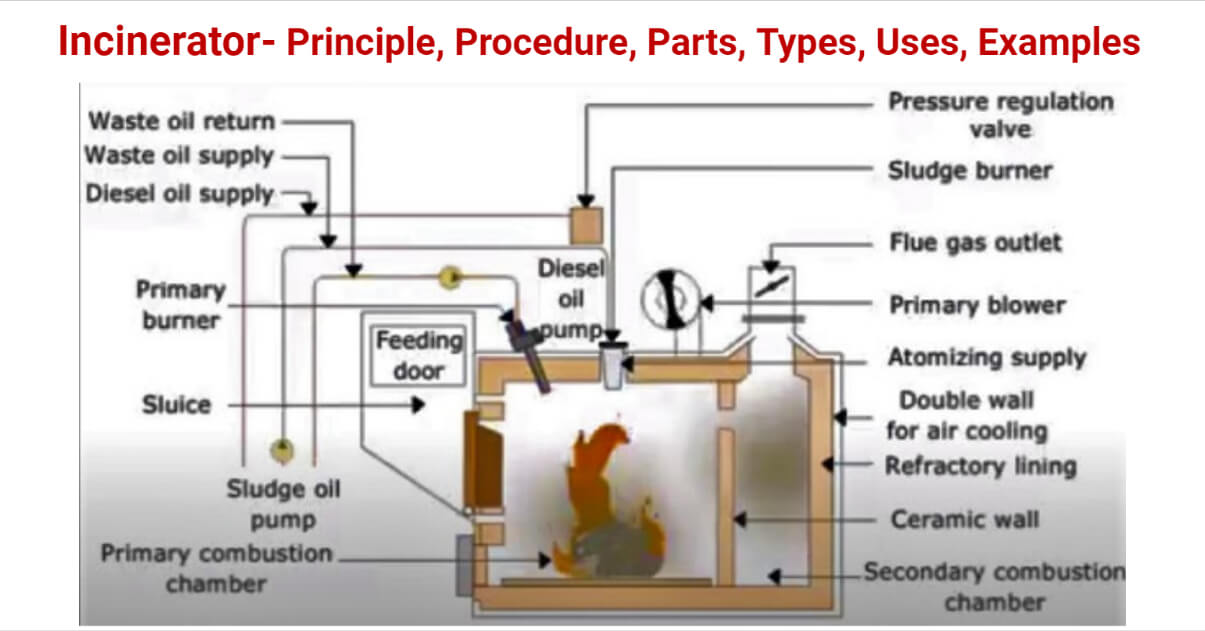

Precept of Incinerator

A main combustion chamber for burning stable waste or sludge oil is included within the design of the incinerator. In distinction, a secondary combustion chamber is included for burning out any unburned exhaust gases. A main burner is put in within the main combustion chamber. This burner receives diesel oil to ignite it initially. After that, the first burner receives the sludge oil till it ignites, manually or robotically turned off. The sludge burner receives atomizing air to facilitate efficient combustion. On the sludge return line, there’s a pressure-regulating valve that can be utilized to regulate the quantity of sludge that enters the conversion chamber. The stable waste will dry out and start burning when the first burner’s warmth is utilized, and the sludge oil may additionally catch hearth. The gases from the first combustion chamber will burn out within the secondary combustion chamber. The first and secondary combustion chambers are divided by a wall of ceramic heavy-duty refractory liners. Stable waste is fed into the incinerator by the feeding door in instances of stable waste or rubbish. The first burner can’t be lit if this door is open, however the remainder of the combustion course of continues as ordinary.

Working process of Incinerator

- The first combustion chamber of the incinerator is meant for burning stable waste or sludge oil, whereas the secondary combustion chamber is meant for burning off any unburned exhaust fumes. A main burner is put in within the main combustion chamber, which receives diesel oil to ignite it initially. After that, the first burner receives the sludge oil till it ignites.

- The first burner is then turned off manually or robotically.

- For efficient combustion, the sludge burner receives atomizing air.

- To manage the quantity of sludge coming into the conversion area, a pressure-regulating valve is equipped on the sludge return line.

- The first burner’s warmth will trigger the stable waste to dry out and start burning, in addition to ignite the sludge oil.

- The first combustion chamber’s monumental transmission space optimizes the stable waste’s drying and burning.

- The first combustion chamber’s gases will burn out within the secondary combustion chamber. The first and secondary combustion chambers are separated by a wall of ceramic heavy-duty refractory liners.

- Stable waste is fed into the incinerator by the feeding door when it’s stable rubbish or waste.

- The first burner can’t be lit if this door is open, however the remainder of the combustion course of continues as ordinary.

Components of Incinerator

The frequent elements of the incinerator are as follows:

Main chamber: All rubbish might be fed into the first chamber and burned for the primary time there. The first chamber is the place the waste vapourises. The low air-to-fuel ratio on this starved-air chamber causes the waste to dry out and makes it simpler for it to evaporate, burning up a lot of the carbon.

Secondary chamber: Waste-derived risky/gasified substances are transferred to the secondary chamber. To finish combustion, extra air is injected within the second stage into the risky gases created within the preliminary chamber. Temperatures within the secondary chamber are increased than these within the main chamber. As a result of applicable residence time, excessive temperature, and 100% surplus air within the secondary chamber, the gaseous merchandise (risky materials) are oxidized. The gases are dealt with after they exit the secondary chamber.

Lastly, the gases are launched to the droplet separator, the place the moisture is taken out of the gases. This lowers the temperature of the flue gasoline, making it secure to launch into the environment.

Flue Stack: The time period “chimney” additionally applies to the flue stack. Stack top necessities for many incinerators are 3 meters or better. In additional populated locations or the place the environment requires it, this requirement might be better.

Management panel and thermocouples: These regulate the machine’s operation and assure that the chambers are heated up earlier than any waste is loaded for incineration. Relying on the kind of waste, the settings might be tailor-made to the operator’s wants.

Burners: These are utilized to heat the incinerator up and are sometimes turned off all through the burning course of.

Gasoline tanks: The gasoline is saved in storage. Through the operation of the incinerator, the burners may have direct traces into the tank.

Forms of Incinerator

In business use, there are totally different classes of combustion applied sciences:

- Rotary Kiln Incinerator

- Fluidized Mattress Incinerator

- Transferring Grate Incinerator

- A number of Fireplace Incinerator

- Liquid injection Incinerator

- Catalytic combustion chamber

- Waste gasoline flare incinerator

- Mounted Grate Incinerator

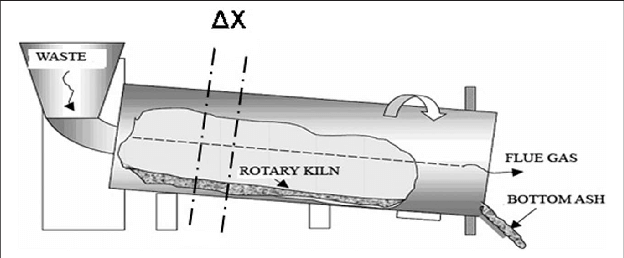

1. Rotary Kiln Incinerator

The essential design consists of two thermal therapy chambers: a main chamber that’s barely slanted and into which waste is fed (together with sizzling exhaust air containing oxygen), rotated, and thermally decomposed by warmth radiation from the secondary chamber; and a recombustion chamber that’s situated in the back of the kiln and into which the decomposition air and the remaining waste is totally burned with the provision of secondary air. It’s constructed with a rotating combustion chamber that retains the rubbish circulating frequently. The waste can vaporize, which makes burning simpler. By modifying the inclination angle and rotational fee of the kiln, the waste throughput fee might be managed. Solids burnout charges and particulate entrapment within the flue gasoline are increased for rotary kiln incinerators than for different incinerator designs as a result of waste’s turbulent movement within the main chambers. Due to this, gasoline cleansing equipment are steadily added to rotary kiln incinerators.

Some great benefits of rotary kilns embody much less NOx manufacturing and warmth elimination of harmful compounds.

In a rotary kiln incinerator, typical waste sorts that may be handled embody Pharmaceutical waste, Hazardous waste, and Medical waste, reminiscent of sharps, infectious waste, surgical trash, medical waste, laboratory waste, and so forth.

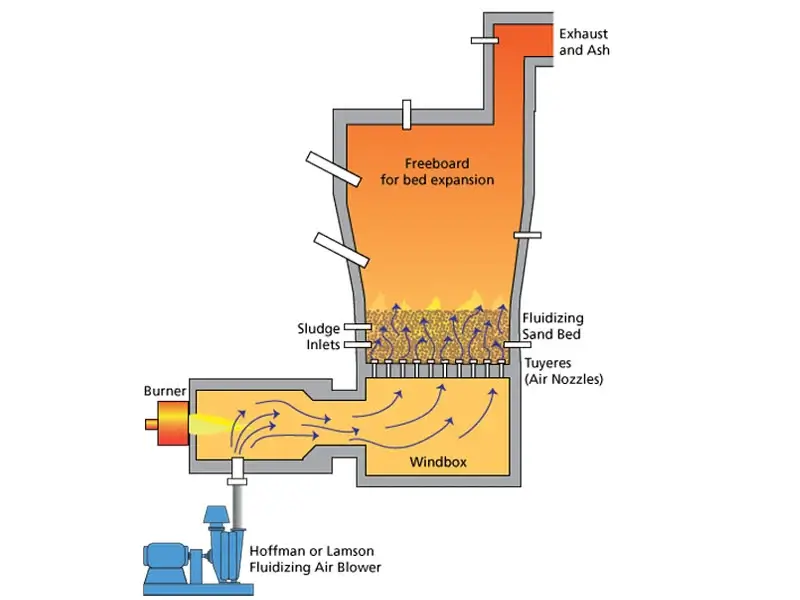

2. Fluidized Mattress Incinerator

The method by which a fluid is handed by granular materials in a stable state to alter it right into a fluid-like state is called the precept of fluidization. The reactor usually contains a vertical metal vessel lined with refractory materials and a mattress of granular materials, reminiscent of limestone, silica sand, or ceramic materials.

Air is injected into the mattress by a number of nozzles on the backside of the incinerator to maintain it fluid. This ends in a violent agitation of the mattress materials the place the burning of trash takes place in shut contact with the mattress materials and combustion air. Due to the comparatively low additional air stage made attainable by this, a excessive thermal effectivity of as much as 90% is feasible.

These are employed within the incineration of sewage sludge and industrial waste and are primarily used for homogenous waste sorts, together with liquid waste.

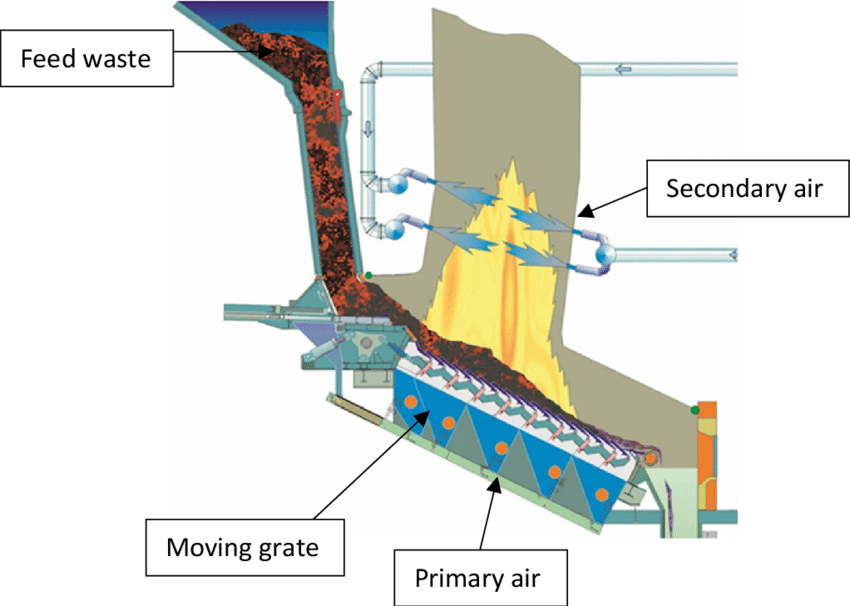

3. Transferring Grate Incinerator

The waste is burned in layers on the grate that strikes the waste by the furnace in a conventional mass-burning incinerator based mostly on a transferring grate. On the grate, the waste is dried earlier than being burned at a excessive temperature with an air provide.

The non-combustible waste fractions, which embody the ash, exit the grate by the ash chute as slag (backside ash). The underside ash (slag), which drops into the water entice of the slag pusher from the grate’s finish, is then cooled by coming into contact with cooling water earlier than transferring on to the conveyor system. Usually, 10 to 25 p.c of the load of the waste feed is made up of slag.

The principle advantages of the transferring grate are its well-proven know-how, capacity to just accept extensive variations in waste composition and warmth values, and skill to be produced in extraordinarily massive models. The first downside is the expense, which is comparatively vital for funding and upkeep.

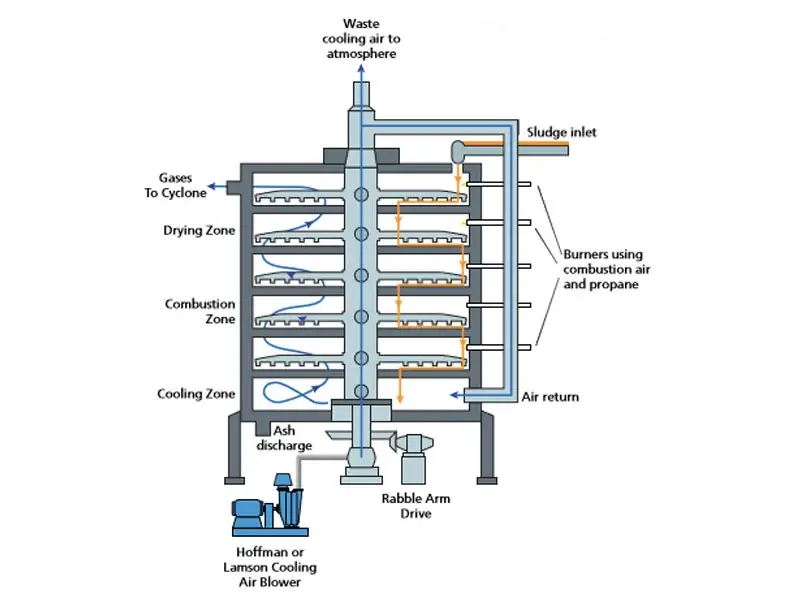

4. A number of Fireplace Incinerator

A a number of fireplace incinerator consists of a row of round hearths organized in a column and guarded by a metal shell lined with refractory with working temperatures starting from 1400 to 1800°F. The feed materials is moved throughout every fireplace in a spiral sample by rabble arms hooked up to a vertical rotating shaft that runs by the furnace’s heart earlier than dropping by the openings into the fireplace beneath. The completed product is ejected by an outlet after traversing by every fireplace.

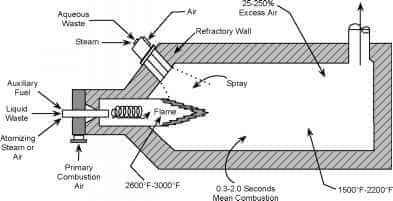

5. Liquid Injection Incinerator

A steadily used system that makes use of excessive strain to separate liquid wastes into tiny droplets for fast burning. Wastes are delivered by nozzles and atomized into small droplets to allow the best attainable mixing with air with working temperatures starting from 1200 to 3000°F. The feed should behave as a liquid with a viscosity of not more than 10,000 ssu. A stable can be utilized if it may be melted and pumped and may fully combust natural flamable materials and non-combustibles like impurities in water.

6. Catalytic combustion chamber

Within the Nineteen Seventies, Engelhard Corp. found the process. It’s a chemical course of that makes use of a catalyst to speed up the specified oxidation reactions of gasoline and restrict the creation of undesirable merchandise, particularly polluting nitrogen oxide emissions (NOx), effectively beneath what is feasible with out catalysts. It’s meant particularly for low natural focus waste.

7. Waste-Gasoline Flare Incinerator

In lots of industrial actions, together with oil-gas extraction, refineries, chemical crops, the coal business, and landfills, undesirable or extra gases and liquids are discharged. Gasoline flaring is a combustion system used to burn these gases and liquids. A considerable supply of greenhouse gasoline emissions is gasoline flaring. Moreover, it produces warmth and noise and renders quite a lot of area uninhabitable. It’s used for non-hazardous waste with excessive natural content material.

8. Mounted Grate/ Direct-Flame Incinerator

It’s usually essentially the most broadly produced and utilized. Gasoline and oxygen are used to take care of the direct flame, permitting trash to be burned. When waste gasoline incorporates particles, direct flame incinerators are employed. They run between 1000 and 1500 °F.

Functions of Incinerator

Medical waste

Medical wastes generated from laboratories, hospitals, and well being clinics can pose well being dangers if not correctly handled or disposed of. Incinerators are designed to destroy and neutralize medical waste.

Animal waste

Incinerators are employed to get rid of animal wastes, together with carcasses, waste, and byproducts, thereby stopping the unfold of an infection and viruses.

Common waste

Common wastes embody much less dangerous wastes from websites reminiscent of mining, small communities, and navy operations, which should be destroyed to scale back environmental influence. Thus, incinerators are devised to incinerate such wastes.

Nanomaterial wastes

Incinerators are utilized to get rid of nanomaterial wastes reminiscent of client merchandise in municipal stable waste, wastes from nanotechnology analysis and improvement, hazardous wastes, and so forth.

Benefits of Incinerator

- Incinerators can cut back the overall quantity of rubbish by as much as 95% and the stable portion of the unique waste by as much as 80–85%.

- Waste administration might be facilitated and improved upon considerably by incineration. Landfills solely allow natural breakdown, whereas non-organic waste continues to construct up.

- Waste is transformed into vitality in incinerators, which might be utilized to supply warmth or energy.

- In comparison with landfills, stable waste incinerators are much less more likely to contaminate the atmosphere.

- Waste incineration amenities might be situated near cities or cities as a result of they require much less area. This has the benefit of lowering the necessity for lengthy drives to dump waste.

- Waste is burned inside a facility the place the byproducts of the incineration course of might be regulated. Due to this fact, waste incineration crops generate a much less disagreeable odor than landfills. It’s because open-air degradation of waste, which provides to air air pollution, is prevented.

- Waste incineration amenities are safer and higher for the atmosphere as a result of they don’t emit methane.

- Incineration amenities burn processed waste at extraordinarily excessive temperatures, killing hazardous micro organism and chemical compounds.

- Since incinerators burn waste with out leaks, they don’t seem to be restricted by variations within the climate.

Limitations of Incinerator

- An incinerator plant’s development requires costly infrastructure and gear, which drives up the price of the set up process.

- Regardless that rubbish incinerators emit far fewer pollution than landfills do, they nonetheless have a substantial influence on air pollution, particularly within the neighborhood.

- Communities with waste incinerators usually tend to expertise long-term destructive well being results like most cancers, beginning defects, reproductive dysfunction, neurological points, and different circumstances identified to happen at very low exposures to most of the metals and pollution launched by incinerators.

- Operation and administration of incinerators demand costly and extremely skilled labor.

Precautions

- To keep away from cross-contamination, scrapes, and punctures from sharps, use heavy-duty gloves and full-body aprons.

- Earlier than burning, sorting the waste reduces operator dealing with time and lowers the hazard of illness, an infection, and injury. This may be achieved by making use of the medical waste shade coding scheme.

- Operators will need to have PPE kits because the extraordinarily excessive temperatures pose a severe threat to everybody concerned.

- If lengthy hours of labor are vital, eye safety utilizing the right shade of security glass could assist to restrict publicity to the eyes.

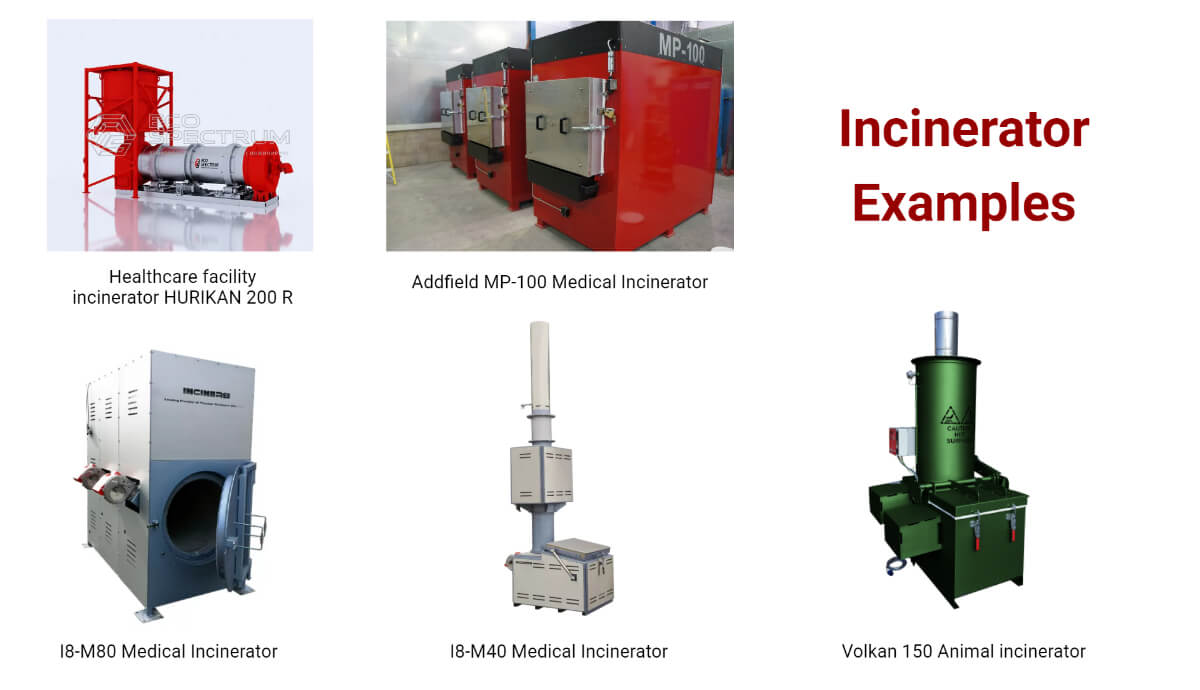

Incinerator Examples

1. Healthcare facility incinerator HURIKAN 200 R (Eco-Spectrum LLC)

- Opposite to brick linings, solely the Eco-Spectrum agency employs particular concrete monolithic linings in rotary incinerators, which assures the shortage of technological gaps on the connecting factors.

- As a result of ceramic plate (positioned between the metallic physique of the furnace and concrete), the operation is allowed at excessive temperatures exceeding 850°C, which significantly reduces gasoline consumption and avoids heating the drum furnace physique from the skin.

2. Addfield MP-100 Medical Incinerator (Addfield Environmental Methods)

- A small to medium-sized medical incinerator that may safely eradicate varied medical and medical waste, together with excessive moisture, pharmaceutical, and organic waste.

- The MP-100 is a small medical incinerator incorporating its secondary chamber inside its thick metal outer shell. This, together with 180mm of superior insulation, ensures that the MP-100 delivers wonderful outcomes whereas being fully secure to function in comparison with inferior machines that lose warmth in the course of the course of.

3. I8-M80 Medical Incinerator (Inciner8)

- The i8-M80 is a medium capability specialist “M” incinerator for disposing medical waste. It has cylindrical combustion chambers, an built-in I.D. fan, and a medical exterior design, making it the proper alternative for hospitals and medical waste assortment amenities.

- It’s self-contained and has a rear entry door that may accommodate a built-in gasoline tank and mounted management panel. The I8-M80 is delivered fully assembled, with a gasoline tank and plumbing included.

4. I8-M40 Medical Incinerator (Inciner8)

- The medical incinerator i8-M40 is simple to make use of and dependable. It was created for little medical establishments, dental workplaces, or different small clinics with minimal waste streams.

- The i8-M40 has a medium-capacity mannequin. Elevated insulation, an improved CE2-VFD management panel, and an I.D. fan improve efficiency and supply all-around appropriateness for varied medical, medical, pharmaceutical, and dangerous waste streams.

5. Volkan 150 Animal incinerator (Eco-Spectrum LLC)

- The case of Volkan 150 Incinerator is constructed of high-carbon metal and has a minimal thickness of 4 to five mm. Together with metal elements, the configuration determines the thickness and alloy of the metal.

- Attributable to insulating supplies in a concrete-lined configuration, the VOLKAN 150 incinerator physique can not assist thermal hundreds. The working floor that comes into contact with the burning waste is the combustion chamber’s lining.

- The warmth-resistance layer of the paint and lacquer coating of the case improves the set up’s longevity when used exterior of buildings and different buildings.

References

- https://www.epa.gov/websites/default/information/2015-04/paperwork/a_citizens_guide_to_incineration.pdf

- https://www.marineengineersknowledge.com/2021/06/incinerator.html

- https://www.conserve-energy-future.com/advantages-and-disadvantages-incineration.php

- https://www.irjet.internet/archives/V4/i12/IRJET-V4I1270.pdf

- https://www.inciner8.com/how-an-incinerator-works

- https://www.inciner8.com/weblog/waste-management/what-are-incinerator-machines-an-idiots-guide

- https://slideplayer.com/slide/10814404/

- https://www.rpi.edu/dept/chem-eng/Biotech-Environ/incinerator.html

- https://www.medicalexpo.com/prod/addfield-environmental-systems/product-100393-652610.html

- https://www.medicalexpo.com/prod/inciner8/product-115640-876343.html

- https://www.medicalexpo.com/prod/inciner8/product-115640-796100.html

- https://www.medicalexpo.com/prod/eco-spectrum-llc/product-128354-1064290.html

- https://www.medicalexpo.com/prod/eco-spectrum-llc/product-128354-957625.html

- Lombardi, F., Lategano, E., Cordiner, S., & Torretta, V. (2013). Waste incineration in rotary kilns: a brand new simulation combustion software to assist design and technical change. Waste administration & analysis: the journal of the Worldwide Stable Wastes and Public Cleaning Affiliation, ISWA, 31(7), 739–750. https://doi.org/10.1177/0734242X13484187

- Bourtsalas, A.C., Huang, Q., Zhang, H., & Themelis, N.J. (2020). Power restoration in China from stable wastes by the transferring grate and circulating fluidized mattress applied sciences. Waste Disposal & Sustainable Power, 2, 27-36.

- https://frtr.gov/matrix2/health_safety/chapter_24.html