Statistical optimization for biocellulose manufacturing by multifactorial experiment

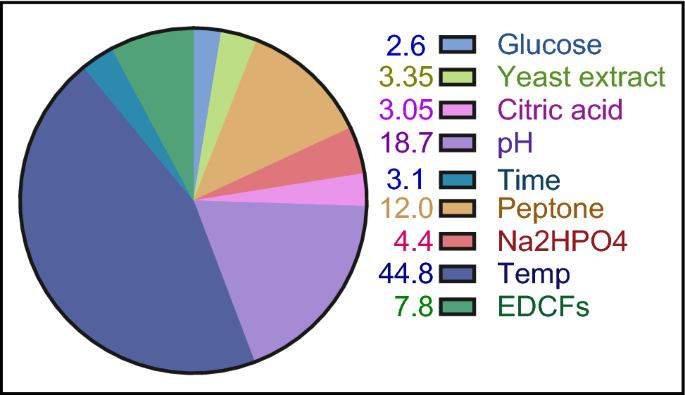

Statistical optimization for biocellulose manufacturing by multifactorial experiment was carried out following two approaches, Plackett–Burman design (PBD) (the primary method) to find out the relative significance of cultivation variables that have an effect on the era of biocellulose from Komagataeibacter hansenii AS.5 utilizing EDCFs based-medium. The PBD, proven in Desk 1, contains 9 variables, particularly, glucose, yeast extract, peptone, citric acid, pH, time, Na2HPO4, temperature and EDCFs. The regression coefficient of glucose, yeast extract, citric acid, pH and time had proven a good constructive impact on biocellulose biosynthesis, nevertheless, peptone, Na2HPO4, temp and EDCFS had a detrimental affect. The 9 variables have been investigated utilizing a linear a number of regression evaluation method and the % confidence degree was derived utilizing the components: confidence degree (%) = (1− p worth)* 100. As well as, the primary impact was estimated because the distinction between the typical measurements of every variable taken at a excessive (+ 1) and low (1) degree. On this experiment, the worth of the dedication coefficient R2 was 0.87 for BC manufacturing, indicating a excessive diploma of correlation between the experimental and predicted values. The polynomial mannequin describes the connection between the 9 elements and the biocellulose focus yield as follows:

$${textual content{Y}}_{{textual content{cellulose yield}}} ,{ = },{0}{textual content{.3705}},{ + },{0}{textual content{.0115X}}_{{1}} ,{ + },{0}{textual content{.01483X}}_{{2}} { – 0}{textual content{.0535X}}_{{3}} { – 0}{textual content{.0195X}}_{{4}} ,{ + },{0}{textual content{.0135X}}_{{5}} ,{ + },{0}{textual content{.08283X}}_{{6}} { – 0}{textual content{.198X}}_{{7}} ,{ + },{0}{textual content{.0138X}}_{{8}} { – 0}{textual content{.0345X}}_{{9}} {.}$$

We employed EDCFs lysate as a medium spine (carbon and nitrogen supply) for BC manufacturing because the utilization of substituted vitamins vastly lowers the manufacturing prices and in addition diminishes environmental degradation introduced on by improperly discarding industrial waste.

The pH, temperature, and cultivation methodology are bodily elements that have an effect on the BC’s microbial productiveness. Additionally, the medium’s compositions (carbon, nitrogen and components) are one other crucial parameters affecting this bioprocess. Two sequential optimization methods (PB and BB) are thought of fashionable selections for product optimization41,42,43,44. Herein, BC manufacturing was optimized utilizing the EDCFs as sources of carbon and nitrogen via making use of statistical experimental designs. The PB design presents a handy, fast screening course of and quantitatively calculates the importance of an enormous variety of elements. This protects time and preserves proof regarding every component45. Even when this mannequin doesn’t present for interplay, the screening programme doesn’t place a excessive premium on wanting into how these quite a few components work together with each other43.

Of all studied variables, solely the simplest and advantageous ones can be chosen for additional optimization, whereas these having a major detrimental affect on the bioprocess is likely to be eradicated from all future checks. The big selection of PB outcomes on this investigation, from 0.34 to 0.65 g/L of BC, highlights the importance of medium tuning for reaching larger productiveness.

Evaluation of the regression coefficients, t take a look at, and p values for the 9 parameters revealed that glucose, yeast extract, citric acid, pH and time had constructive results on the biosynthesis of BC, however peptone, Na2HPO4, temperature, and EDCFs had adversarial results. That is in settlement with Hegde et al.46 who discovered the simplest parameters for BC manufacturing have been glucose, yeast extract, however is in disagreement with Singh et al.47 who reported that pH had a detrimental impact on bacterial cellulose manufacturing.

In accordance with these outcomes, a medium with the next composition (g/L): glucose, 6; yeast extract, 5; Na2HPO4, 2; citric acid, 1.5; pH, 7; temp, 20 °C; EDCFs waste, 100 ml; time, 10 days, with cellulose focus, 1.003 g/L, was used as the fundamental medium for the following design.

Temperature, pH, and EDCFs have been chosen as a result of they considerably have an effect on BC synthesis and have a larger confidence degree, as proven by a pareto chart (Fig. 2). This chart was illustrated through the use of EdrowMax software program (https://www.edrawsoft.com/download-edrawmax.html). With a view to simplify the medium and rely totally on EDCFs lysate as a medium spine, two verification checks have been utilized. The primary used the everyday medium and circumstances really useful by the PB equation mannequin, whereas the second didn’t embrace peptone. Each experiments gave roughly the identical yield of BC (1 g/L). Due to this fact, peptone was omitted from the medium within the subsequent experiment.

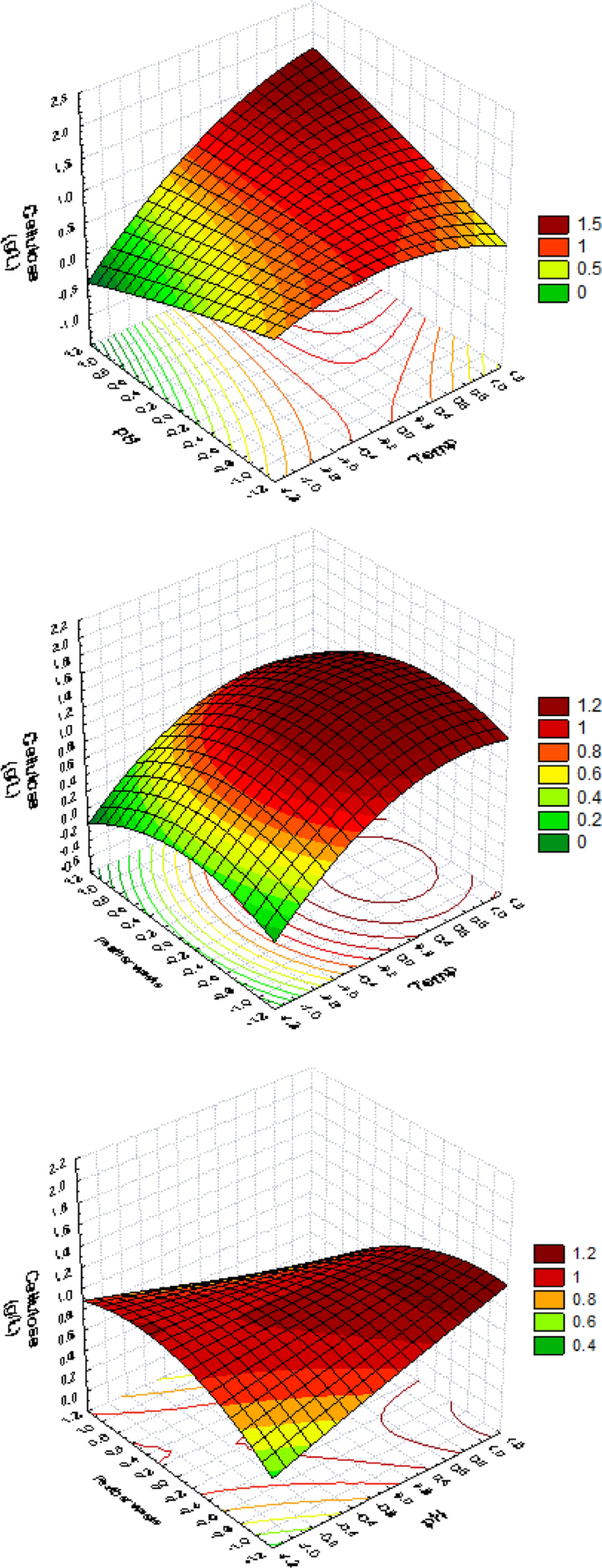

Accordingly, the main unbiased variables (X1; temp, X2; pH, X3; EDCFs waste lysate) have been additional studied at three ranges, utilizing Field–Behnken design (BBD) (the second method) to search out the optimum response area for biocellulose synthesis when it comes to g/L (Desk 2). The three variables have been studied utilizing a linear a number of regression evaluation method with fourteen trials, and the share confidence ranges (%) have been calculated as beforehand described. The dedication coefficient R2 = 0.87 for BC focus, which is a measure of mannequin match, indicating that solely 13% of the responses couldn’t be fitted throughout the utilized mannequin. The usage of floor plots to current experimental information demonstrates that larger ranges of cellulose manufacturing have been achieved with decrease EDCFs lysate and better ranges of temperatures and pH, as proven in Fig. 3. A second-order polynomial perform was fitted to the experimental outcomes for estimating the optimum level of variable inside experimental constraints (non-linear optimization algorithm:

$${textual content{Y}}_{{textual content{cellulose yield}}} ,{ = },{1}{textual content{.2825}},{ + },{0}{textual content{.4065 X}}_{{1}} ,{ + },{0}{textual content{.02 X}}_{{2}} { – 0}{textual content{.122 X}}_{{3}} ,{ + },{0}{textual content{.434 X}}_{{1}} {textual content{X}}_{{2}} { – 0}{textual content{.032 X}}_{{1}} {textual content{X}}_{{3}} { – 0}{textual content{.24 X}}_{{2}} {textual content{X}}_{{3}} { – 0}{textual content{.33}}left( {{textual content{X}}_{{1}} } proper)^{{2}} { – 0}{textual content{.081}}left( {{textual content{X}}_{{2}} } proper)^{{2}} { – 0}{textual content{.272}}left( {{textual content{X}}_{{3}} } proper)^{{2}} {.}$$

The optimum ranges of the three examined variables, as decided by the polynomial mannequin’s most level, have been temperature, 23; pH, 8; and EDCFs waste-lysate, 75.26 ml/L, with a predicted cellulose focus of 1.86 g/L. Lastly, to check the quadratic polynomial’s accuracy, a verification experiment was performed below predicted optimum circumstances, measuring biocellulose manufacturing within the optimized medium.

The % accuracy of the mannequin was obtained utilizing the next components to reveal its accuracy: mannequin accuracy = [Y Experiment/Y Calculated] 100. The Y worth is 2 g/L, in keeping with bench scale research. The accuracy of the calculated mannequin was 107.5%. On this work, a statistical methodology based mostly on a mix of PB and BB designs was discovered to achieve success and correct in figuring out statistically necessary elements and figuring out their optimum concentrations. Consequently, the next medium composition (g/L) is estimated to be near the optimum: glucose, 6; yeast extract, 5; Na2HPO4, 2; citric acid, 1.5; pH, 8; temperature, 23 °C; EDCFs waste, 75.26 ml; and time, 10 days below static situation, the place BC focus was 2 g/L and the yield elevated twofold in contrast with manufacturing from the PB design.

Experimental information introduced as floor plots reveals that prime BC manufacturing yield is supported by larger temperatures and pH ranges, even at comparatively low EDCFs lysate waste ranges.

For BC manufacturing, the R2 worth was 0.87, indicating a robust affiliation between experimental and forecast values. Experimentally, the confirmed optimum circumstances from the optimization experiment have been in comparison with the mannequin’s anticipated worth. The estimated BC focus was 2.1 g/L, and the expected worth from the polynomial mannequin was 1.87 g/L. This excessive degree of accuracy (107.5%) reveals that the mannequin was validated below supreme circumstances; moreover, the BC focus decided by BBD was 2 instances larger than PBD. This demonstrates the importance and necessity of the optimization course of. Our analysis helps the findings of46,48, they declare that the RSM is a usually accepted trendy statistical technique for the optimization of the experiment’s total circumstances and the answer of the evaluation issues. RSM assists in figuring out the crucial variables for finding out interactions, figuring out the optimum variety of variables, and making certain the very best output in a restricted variety of checks49. In conclusion, using EDCFs for BC manufacture can save manufacturing prices and environmental air pollution.

Statistical evaluation

“JMPIN Model: 4.0.4 software program was used to carry out the experimental designs and statistical evaluation and STATISTICA software program model 7 was used to attract 3D floor plots”.

Chemical construction characterization of BC membranes

Fourier remodel infrared (FTIR) spectroscopy-analysis

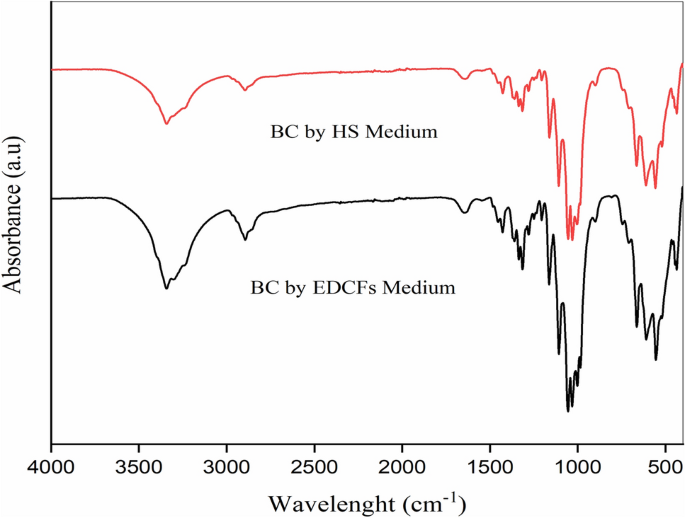

The chemical construction of the BC membrane based mostly on EDCFs medium was in contrast with the usual HS medium, the place FTIR spectra of each BC membranes are proven in Fig. 4. Principally, no variations in attribute peaks of BC in both HS medium or based mostly on EDCFs medium have been noticed50. It was noticed that the absorption band assigned to the –OH teams of cellulose seems at ν 3350 cm−1. Different cellulose-specific peaks have been discovered at ν 2894, 1427, 1350, 870 and 655 cm−1 that are assigned to –CH stretching bands, (HCH, OCH) bending within airplane vibration, –CH deformation vibration, (COC, CCO, CCH) deformation mode stretching vibrations, and C–OH banding out of airplane; respectively50,51.

X-ray diffraction (XRD) evaluation

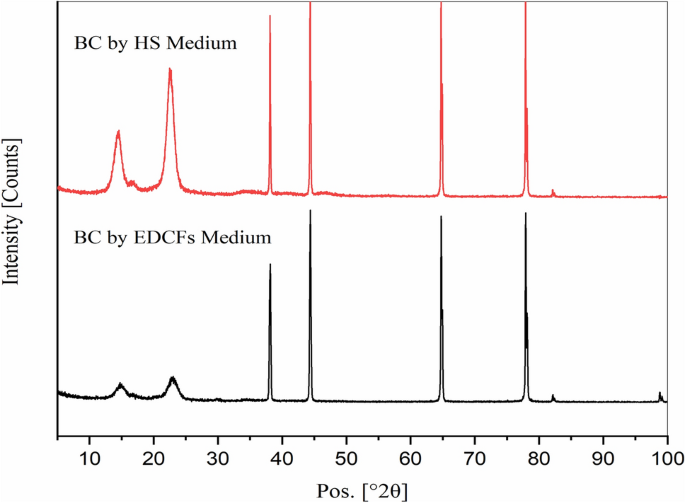

Determine 5 illustrates the XRD diffraction patterns of each two BC obtained by HS medium and by EDCFs optimized medium. As seen in Fig. 5, no variations within the attribute peak patterns of two BC membranes are noticed. The diffraction diagrams of BC reveal greater than two attribute diffraction peaks, indicating that BC incorporates Iα and Iβ crystal cellulose. Typically, two BC membranes present a excessive diploma of crystallinity or crystallinity-index between 90–95%, the place two BC membranes reveal the attribute diffraction peaks at 2θ = 16° and 25° with interplaner spacing (d-spacing) 3.91 and a pair of.32, respectively50. In the meantime, different diffraction peaks are noticed at 2θ = 38°, 45°, 64° and 78° which point out the presence of unreacted or unconverted glucose or amino acids residues of BC obtained from HS medium or produced BC from EDCFs medium, respectively50,52.

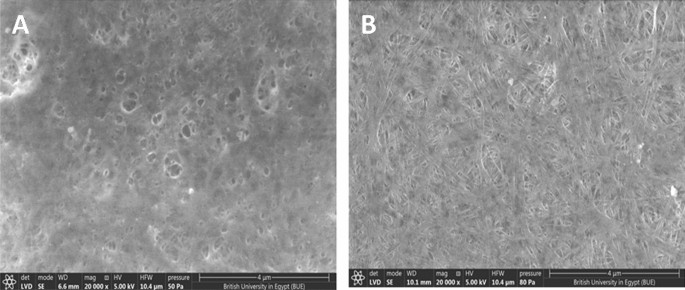

Scanning electron microscopy (SEM) investigation

The morphological properties of BC membranes, which have been produced by each HS and EDCFs medium, have been examined by SEM with totally different unique magnifications at 10,000 and 20,000X, as proven in Fig. 6. As seen, the floor morphology of BC membrane based mostly on EDCFs appears to be extra uniform, with a filamentous form construction, ribbon-fibril networks, and pours much less, significantly with excessive magnification, in comparison with conventional bacterial cellulose produced by HS medium (Fig. 6). Notable, fibers of BC produced by EDCFs medium diameters have been discovered to be a mean of fifty–100 nm, whereas diameters of bacterial cellulose produced by HS medium have been discovered to be between 100–150 nm. The present SEM investigation is sort of per SEM investigations as beforehand reported by Tsouko et al.53 and Zhang et al.54.

Characterization of SEDCFs

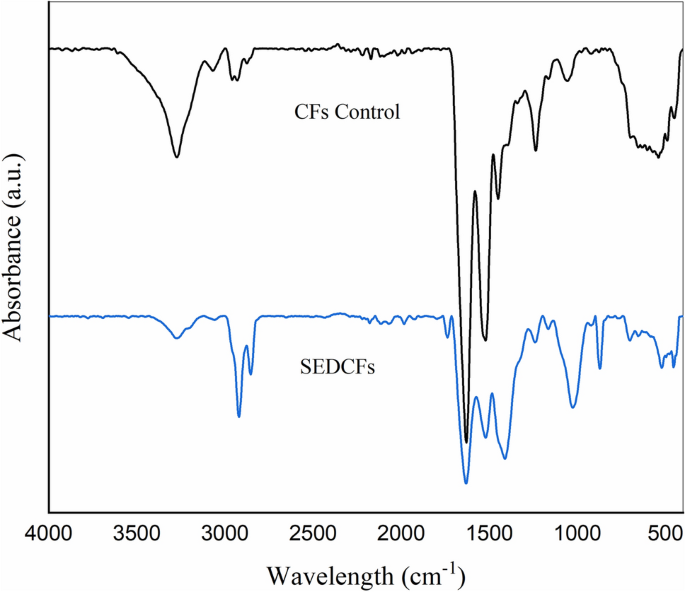

FT-IR evaluation

For understanding the chemical construction of pristine CFs and SEDCFs, FT-IR spectra have been performed (Fig. 7). After comparability of management CFs and handled SEDCFs samples, it was noticed that the attribute peaks are principally comparable to one another and are comparable with one another. Then again, the chemical construction of SEDCFs displays little impact on the chemical construction of protein after degradation (Fig. 7, proper). The transmission band area between ν 3500–3200 cm−1 in CFs, was shifted to ν 3500–3000 cm−1 in SEDCFs on account of starching vibration of –O–H and –N–H of amide A. Nevertheless, bands that appeared within the vary between ν 3000–2800 cm−1 have been associated to symmetrical –CH3 stretching vibration in handled SEDCFs, solely52,53. Curiously, in case handled SEDCFs; robust absorbance band at 1730–1630 cm−1 which is attributed to C=O stretching of amide I. Additionally, the absorption peak at ν 1520–1410 cm−1 is attributed to N–H bending and C–H starching, of amide II of SEDCFs. Whereas, weak band at ν 1240 cm−1 is related to amide III derived from N–H bending, C–N stretching and a few bending from C=O bending and C–C stretching vibration of SEDCFs. Additionally, a weak peak at ν 700 cm−1 is said to the N–H out-of-plan bending of handled SEDCFs53. Notably, robust vibration peak round ν 1730 cm−1 is attributed to C=O of fatty acid ester present in animal skins, and was detected solely in instances of handled SEDCFs, which confirms that the therapy of degradation doesn’t have an effect on the primary construction of keratin55. Nevertheless, the C–O stretching vibration related to ester linkage, attributed at round 1230 cm−1 was detected in each CFs management and handled SEDCFs50,53,55. General, it was proven that there are not any results on the primary chemical composition of CFs after degradation therapy, however the chemical composition of SEDCFs turns into extra clear and exact.

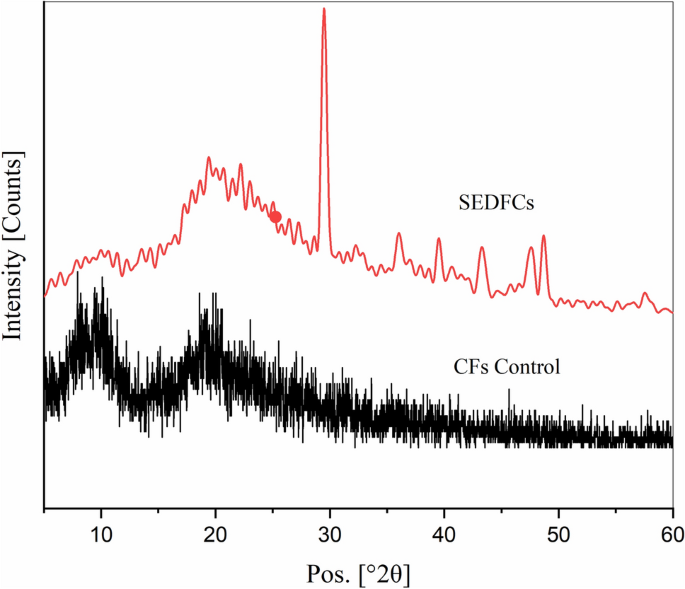

Vast-angle X-ray diffraction (WAXRD)

WAXRD was used to find out the crystal section of the examined CFs management and SEDCFs samples (Fig. 8). The XRD patterns in Fig. 8 present that each CFs and SEDCFs primarily existed within the semi-crystalline section, and even after some hydrolysis, they retained the crystallinity. As seen, CFs present diffraction traits of α-helix showing at 2θ = 9.5° and β-sheet at 2θ = 20.8°, nevertheless SEDCFs exhibit diffraction traits of shifted α-helix showing at 2θ = 10.6° and β-sheet at 2θ = 21.8°50,53,55. Whereas, the diffraction peaks at 2θ = 13° and 16° of CFs and SEDCFs, respectively are allotted for the amorphous area. Additionally, diffraction peaks are allotted at 2θ = 29° and 38° have been listed for theβ-sheet crystalline construction of SEDCFs, whereas the peaks between 2θ = 17°-20° listed for α-helix diffraction patterns of SEDCFs. General, XRD outcomes point out that partial crystallinity of SEDCFs is retained after the enzymatic degradation course of, in comparison with pristine CFs.

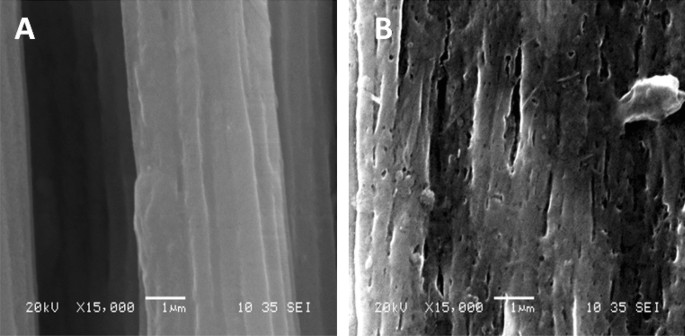

Morphological investigation

The conclusion of untreated and handled CFs morphology was examined through necked eye and utilizing SEM investigation. The outcomes exhibited the presence of all primary elements of CFs even after degradation therapy with minimal differentiation. Nevertheless, additional morphological investigation and elemental analyses have been performed by SEM and SEM–EDX analyses, as proven in Fig. 9, handled and degraded SEDCFs photographs have been displayed with totally different magnifications in Fig. 9. As seen, SEDCFs have been saved considerably erection even after degradation therapy as present in pristine CFs, with a scarcity of woolly-shape construction components as in contrast with management CFs (Fig. 9).

Mechanical properties for coated HSP

The usage of CFs extract as an ecofriendly methodology for the event of composites and coating brokers for the safety of carbon metal from corrosion10. That is the primary report to make use of sludge of enzymatically degraded rooster feathers (SEDCFs) as a coating agent for HSP. The HSP was coated to find out its mechanical efficiency utilizing three totally different concentrations of SEDCFs (1, 2 and three%). Desk 3 reveals the outcomes of mechanical properties, as bulk densities, most load, breaking size, tensile index, Younger’s modulus, work to interrupt, and coating layer. Bulk densities, described because the reciprocal worth of density that specifies the compactness or quantity of the paper, can be utilized to conclude the connection between each the grammage and thickness of paper56. The majority density of clean HSP was extra vital than that reported from coated HSP, indicating the alternative the values of the coated HSPs, bulk density reveals a discount upon growing the content material of SEDCFs, thus suggesting that the presence of SEDCFs could have an effect on the cellulosic fibers of HSP, that is suitable with different research57. Desk 3 reveals that with growing the focus of SEDCFs, the utmost load and breaking size have been elevated; this was because of the robust coated HSP shaped by the motion of coating agent. This result’s in settlement with different work58. The tensile index is (tensile energy/base weight) a mechanical variable that characterizes tensile energy in relation to materials amount. This variable is influenced by the diploma of fiber bond formation59. Outcomes represented in Desk 3 point out that the low worth of the tensile index was noticed within the HSP coated with SEDCFs compared with clean HSP, in order that the tensile index exhibited negligible adjustments in mechanical properties, this can be because of the giant penetration of the coating options into the HSP at excessive coating ratio led to the swelling of the cellulose fibers, which additional decreased their mechanical properties60.This outcomes are per different analysis61.Younger’s modulus results of coated HSP refers to the truth that there isn’t any significance was noticed because of the motion of coated SEDCFs towards to clean HSP. The ensuing SEDCFs -coated HSP confirmed elevated work at break, this outcome indicated the flexibleness of the coated feather over the HSP, this commentary are in settlement with62, who coated the HSP with cellulose stearoyl ester, alternatively, different research reported that with growing the focus of coating agent (cellulose nanofiber/chitosan nanoparticles), the worth of labor at break decreased63. On the whole, a constructive impact on the mechanical conduct of coated HSP is induced by the presence of SEDCFs with a related enhance on each most load and work at break.

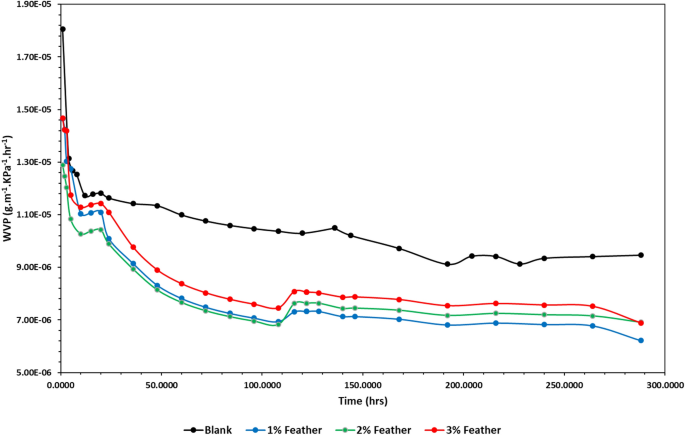

Water vapor permeability (WVP)

The WVP of HSP was outlined because the mass of water vapor passing via the HSP per unit space and time below outlined circumstances. The low WVP values are fascinating for industrial packaging like meals, medication, and devices62.WVP of the coated HSP was estimated as properly and in contrast with the uncoated HSP as introduced in Fig. 10. It’s evident that coated HSP displays larger resistance to WVP in comparison with uncoated HSP. Though SEDCFs have a robust hydrophilic efficiency, the utilization of SEDCFs in paper coating ends in decrease water vapor penetration via the coated HSP and consequently improves hydrophobicity. Particularly, the effectivity of the SEDCFs in decreasing the WVP is obvious even at low focus (1%), reaching an enchancment in WVP as much as 18%. This may very well be because of the low focus of feather extract blocking the pour measurement of HSP.Then again, because the concentrations of SEDCFs elevated the WVP of coated HSP elevated. This defined by the aggregation and coagulation of SEDCFs at excessive focus on the floor of HSP. These findings are per earlier analysis, which discovered {that a} low focus of sodium alginate/nanocellulose/Ag-NPs nanocomposite decreased the WVP of coated, whereas a better focus of cellulose nanocrystal/Ag-NPs elevated the WVP of coated paper64.

Oil resistant barrier (ORB)

The ORB of the coated HSP was investigated and in contrast with the HSP as illustrated in Desk 4. The outcomes confirmed that HSP coated by SEDCFs had outstanding oil resistance when olive oil was evaluated. Herein, HSP and coated HSP have been examined for his or her oil-resistance utilizing the olive oil assay, the place the time required for penetration of olive oil via the pattern is noticed. The outcomes of the take a look at confirmed that coated HSP at totally different concentrations from SEDCFs confirmed wonderful grease proof property because the time wanted for penetration of olive oil was > 600 s, which will be labeled as excessive grease-proof supplies. In addition to, with the SEDCFs focus enhance, the oil resistance of HSP elevated. The coated HSP exhibited a superb ORB (130–600 s) in contrast with the uncoated HSP (80 s). Coatings based mostly on SEDCFs are extremely lipophilic supplies, such that hygroscopic oil doesn’t dissolve in its HSP, resulting in wonderful ORB65. The oil resistance of paper coated with totally different SEDCFs focus exhibited good oil resistance because the SEDCFs focus elevated from (1–3%) because of the excessive hydrophobicity of it, which meets the calls for for meals packaging. A number of research have been reported, the addition of energetic supplies as coated half improve their ORB as cellulose nanofibers/chitosan nanoparticles65, HSP/ZnO/SiO258 and HSP/Microcrystalline Wax Emulsion66.

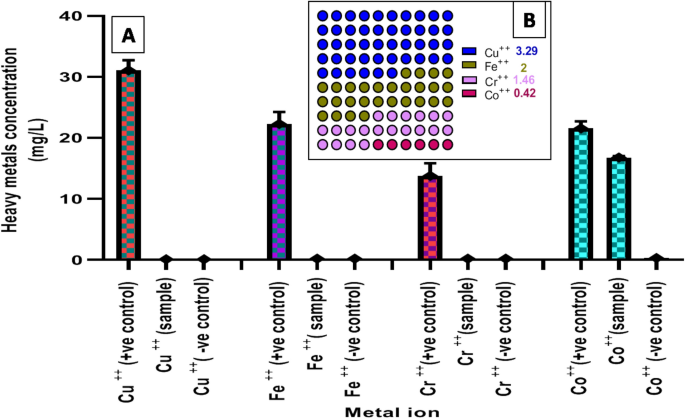

Removing of heavy metals utilizing SEDCFs

Heavy metals accumulation represents an incredible environmental problem attributed to the adversarial results on human and animal well being33. A number of approaches are presently reported for heavy steel elimination. Nevertheless, the fee applied, power consumption, and affect of the environmental impacts of the steel elimination methodology are nonetheless difficult31. Then again, CF is a primary waste within the poultry trade with excessive environmental impacts31. On this regard, the effectivity of the SEDCFs on heavy steel elimination was evaluated towards 4 mannequin steel ions, particularly, Cu++, Fe++, Cr++ and Co++. The outcomes (Fig. 11) point out a major affinity of SEDCFs towards Cu++, Fe++ and Cr++ ,which have been fully faraway from steel options (Fig. 11). The SEDCFs affinity skill towards the three metals was within the following order: Cu > Fe > Cr as indicated within the sorption capability outcomes: 3.29, 2.017 and 1.46 mg/g for the three metals, respectively. The excessive efficiency of feather waste for Cr++ and Cu++ has been reported in different research67.

In the identical regard, the steel elimination was reported for CF in Pb++ elimination from wastewater by de la Rosa et al.68, and in addition for CFs-ash for Cd++ elimination from waste water39. Then again, the SEDCFs revealed a low affinity towards cobalt ions, revealing solely 18% Co++ elimination from aqueous resolution with a sorption capability of about 0.42 mg/g. The outcomes are in accordant with Zhang et al.67 who reported the low affinity of CFs along with three different pure keratin sources, towards cobalt ions, and opposite to Chakraborty et al.35, reporting the alternative. The low affinity towards cobalt ions, within the present research, asserts the selectivity of biologically ready SEDCFs towards totally different metals that may very well be attributed to the various purposeful teams on the SEDCFs sludge particles’ surfaces2,67. As per literature, the CF was hypothesized to remediate heavy metals via floor precipitation along with ion alternate between the CF floor’s Ca++ ions and the focused heavy steel39.